Sindo is a professional wood product manufacturer. We manufacture three types of film faced plywood, namely Anti-slip Film Faced Plywood Sheet, PP Plastic Film Faced Plywood Sheet and Simple Construction Plywood Sheet。

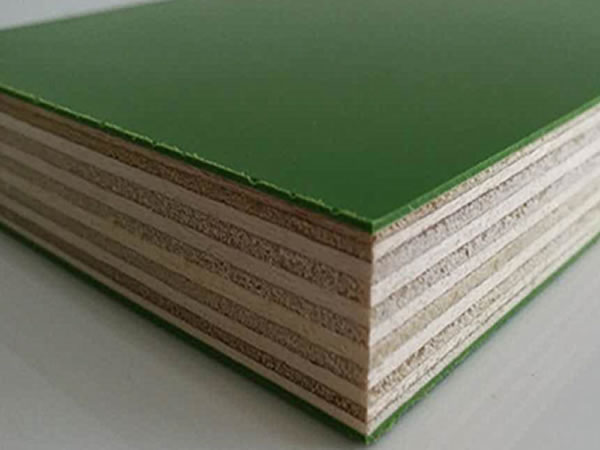

Our film faced plywood is available in different thicknesses. Its core veneer is mainly made of poplar and hardwood。 This product has many characteristics, such as high strength, stability, smooth finish, water resistance, ultraviolet resistance, wear resistance and so on. As a result, it is widely used in the construction of high buildings and bridges, making it an indispensable material in the construction industry.

At Sindo, we are a professional wood panel supplier, offering a variety of film-faced plywood options to meet different project requirements.

Finger joint core film-faced plywood is made from recycled plywood used as the core material.

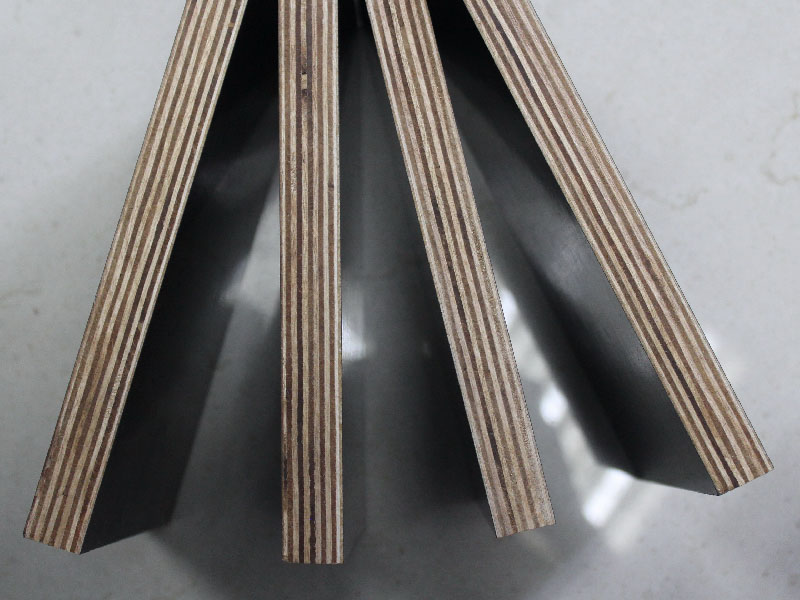

The key difference between this anti-slip film faced plywood and regular film-faced plywood lies in its surface, which is coated with an anti-slip melamine-impregnated film paper, giving the board a reliable anti-slip function.

PP plastic film faced plywood is a new type of film faced plywood, it has following features when compared to traditional film faced plywood.

Sindo has 10 years of experience in the production and supply of wood products. As a renowned film faced plywood supplier, we provide a wide range of products including plywood, medium density fiberboard, high density fiberboard, hardboard, blockboard, and more. Our products have been awarded SONCAP and CE certification. They are very popular in countries such as the USA, Germany, Egypt, Japan, Korea, Canada, Mexico, Argentina, Brazil, and Peru etc.

For more product information, please feel free to Contact Us. Thank you!

Like all materials, the durability of film-faced plywood depends on how and where it is used. In humid environments, materials that absorb moisture are prone to mold and rot. However, film-faced plywood is designed to resist these issues. It is treated with features like edge sealants, anti-mold coatings, and corner reinforcements, reducing the risk of moisture damage.

Compared to other materials, film-faced plywood offers a longer lifespan due to these protective measures, making it a reliable choice for outdoor and high-moisture applications.

The key difference between film-faced plywood and filmless plywood lies in their intended applications, not durability. Film-faced plywood is designed for furniture, decorative purposes, and packaging, it comes with a smooth, finished surface that doesn’t require further treatment. This makes it ideal for applications where aesthetics and ease of use are essential. By othe hand, filmless plywood especially recommended for construction and industrial use, it provides a raw surface that can be custom-finished with coatings like epoxy to enhance gloss or protection. Its versatility makes it ideal for projects where functionality and structural integrity are the priority.

Both types of plywood offer excellent performance but cater to different needs—film-faced plywood for aesthetics and filmless plywood for structural applications.

Film-faced plywood is coated with a high-quality film, providing excellent rigidity and resistance to damage, making it suitable for a variety of demanding applications. One of its primary uses is in concrete formwork, where its durability ensures reliable performance for mold boards in concrete pouring.

In agricultural buildings and food storage facilities, the smooth and hygienic surface of film-faced plywood makes it safe for environments where sanitation is essential. It is resistant to contamination, which is especially beneficial in food-related spaces.

The material is also popular in furniture manufacturing, used to create chairs, tables, sofas, beds, and other household furniture. Its robust surface ensures it can withstand daily wear, offering longevity without compromising aesthetics.

Additionally, film-faced plywood is ideal for industrial environments that require frequent cleaning, as it resists damage from strong cleaning agents. This makes it a practical choice for settings where both durability and hygiene are priorities.

Waterproof film-faced plywood offers superior moisture resistance, making it an ideal choice for environments exposed to humidity, water, and chemicals. This durability ensures reliable performance in applications where traditional materials would degrade over time.

When coated with latex paint or oil-based finishes, the plywood's surface becomes even more resistant to water and wear. Additionally, applying waterproof acrylic coatings enhances both its moisture resistance and abrasion resistance, ensuring long-term durability in demanding environments.

This combination of properties makes waterproof film-faced plywood a preferred material for construction, industrial applications, and furniture in areas where both strength and water resistance are essential.

Film-faced plywood relies on Water Boil Proof (WBP) glue to enhance its durability and moisture resistance. WBP glue ensures that the plywood can withstand boiling water exposure, making it highly water-resistant and extending its lifespan. There are two main types of WBP glue commonly used:

These glue types play a crucial role in ensuring the reliability and longevity of film-faced plywood, especially in construction, industrial, and outdoor environments.

When purchasing film-faced plywood, it’s important to evaluate several key factors to ensure the product meets your specific needs. Consider the product type, length, and thickness, choosing dimensions based on the intended application and ensuring the thickness aligns with the project’s structural requirements. Pay attention to the film coating and whether the plywood has edge protection to guard against moisture and damage.

The quality of the core material and film coating can vary, so selecting plywood that meets your performance expectations is essential. One of the most critical aspects is the type of glue used. Look for plywood with Water Boil Proof (WBP) glue for superior water resistance, ensuring durability, especially in outdoor or high-moisture environments.

By considering these factors, you can be confident that the film-faced plywood you select will provide optimal performance for your construction, furniture, or industrial projects.

Whether you work in architecture, furniture, decoration, packing or any other applications requiring high quality wood products, you can rely on our wide range of products and services exceeding your requirements.