MDF (Medium-Density Fiberboard) and HDF (High-Density Fiberboard) are engineered wood products made from wood fibers or other plant fibers.

Although MDF can be faced with several options, the most commonly used one is melamine. Melamine is a paper film that is impregnated with melamine.

Veneered MDF/HDF combines the natural beauty of real wood veneer with the structural stability of MDF or HDF panels.

Our UV-coated MDF/HDF panels offer an exceptional blend of style and functionality. These panels are produced using a medium or high-density fiberboard core, which is coated with UV-cured lacquer.

In terms of density, fiberboards can be categorized as hardboards, medium-density fiberboards and low-density fiberboards. Hardboard is an engineered wood product that is made out of highly compressed wood fibers.

Embossed hardboard refers to wood fiberboard with raised patterns on the surface, created using specialized patterned molds rather than traditional carving.

Melamine-faced hardboard is a decorative panel made by soaking paper with various colors or textures in melamine resin adhesive.

High-Density Fiberboard (HDF) is a high-performance composite material that is both denser and thinner than traditional particleboard. It is made by compressing fine wood fibers with resin under high pressure and heat, resulting in a strong and durable panel. The smooth, uniform surface and excellent resistance to moisture make HDF ideal for applications that require high strength and stability.

HDF offers several advantages, such as exceptional wear resistance and dimensional stability, preventing warping or splitting due to temperature or humidity changes. Its smooth surface makes it suitable for flooring or painting, and it is also resistant to moisture and mild chemicals, ensuring long-lasting durability. Additionally, HDF has high compressive strength, making it suitable for use in applications that require the material to withstand significant loads from above or below.

Due to its strength and durability, HDF is commonly used in furniture production and cabinetry, where strong load-bearing properties are essential. It is also widely used for high-traffic flooring, as it provides excellent wear resistance and reliability. The material’s smooth surface and resistance to environmental changes make it suitable for wall panels and partitions, especially in environments that experience temperature and humidity fluctuations.

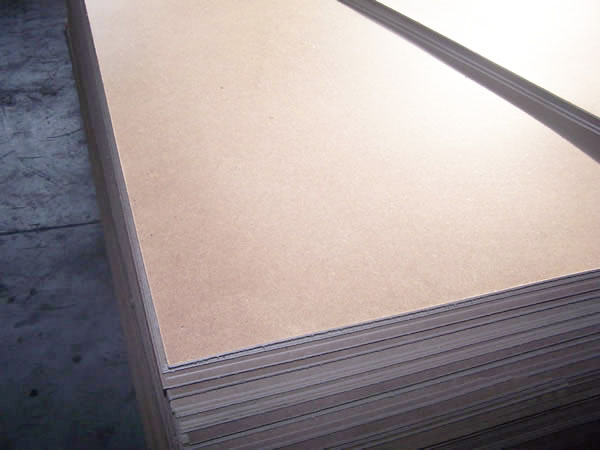

Medium-Density Fiberboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into fine fibers. These fibers are mixed with wax and resin and then compressed under heat and pressure to form flat panels. MDF is valued for its stability and consistency, making it a versatile material for a variety of interior applications, including furniture and cabinetry.

MDF is known for its strength and resistance to shrinking or warping, even in environments with humidity changes. Its smooth surface eliminates the need for additional veneers or laminates, making it easy to paint or coat. MDF is also cost-effective compared to solid wood, making it a practical choice for budget-conscious projects. Additionally, it is easy to cut, drill, and machine, holding intricate designs well without splintering.

MDF is widely used in furniture production, including cabinets, bookshelves, and storage units, offering a smooth surface for paints and finishes. It is also popular in interior design applications, such as wall panels, moldings, and decorative trims, where its smooth surface provides an excellent base for painting. MDF is commonly used for kitchen and bathroom cabinetry, as it resists shrinking and warping, ensuring long-term stability in environments with varying moisture levels.

Whether you work in architecture, furniture, decoration, packing or any other applications requiring high quality wood products, you can rely on our wide range of products and services exceeding your requirements.