Founded in 2002, Sindo is a professional wood-based product manufacturer in China. Through our continuing efforts and years of experience, we can provide a wide variety of wood products for you to choose from. We are located in Shanghai. This location gives us access to convenient transportation by sea, land, and air, which lowers our production costs and your freight charge.

Our plywood panels are highly valued in construction for their high compressive strength and cost-efficiency. Their lightweight, easy-to-handle structure makes them ideal for a variety of building template systems. These panels simplify installation and ensure excellent performance across multiple construction fields, including formwork, scaffolding, flooring systems and wall and roof sheathing.

The versatility and strength of our plywood ensure reliable performance in demanding environments, making it a practical and efficient choice for architectural, industrial, and residential projects.

As a professional plywood manufacturer in China, Sindo specializes in producing a variety of high-quality plywood products tailored for different industries. Our offerings include:

Our sheets are available in custom and standard sizes, meeting the varied needs of our clients across industries. With a focus on both quality and performance, Sindo ensures that each product meets the demands of furniture, construction, and interior design projects. Whether you're building frameworks, designing interiors, or crafting furniture, our wood panels deliver reliability and value.

Plywood is a top choice for the furniture industry due to its smooth, uniform surface quality and versatility. Its strength, lightweight structure, and ability to hold finishes make it ideal for a wide range of furniture and interior applications. Common uses include:

Plywood’s strength and smooth finish ensure long-lasting performance, even in environments that require moisture resistance, such as kitchens, bathrooms, and marine settings. As a reliable wood manufacturer, we offer a variety of plywood options to meet the needs of furniture makers and interior designers worldwide.

Plywood plays a crucial role in the production of trailers, semi-trailers, and vehicle bodies, thanks to its strength, durability, and versatility. Depending on the application, different types of plywood are used, each offering specific benefits.

Our plywood panels are manufactured by bonding multiple wood layers with specialized adhesives under high pressure. This process ensures exceptional abrasion resistance, impact strength, and water resistance, making them ideal for demanding uses in trailer, semi-trailer production, vehicle body construction, container flooring. With their high resistance to wear, water, and external forces, these plywood panels are the preferred choice for both transportation vehicles and industrial applications.

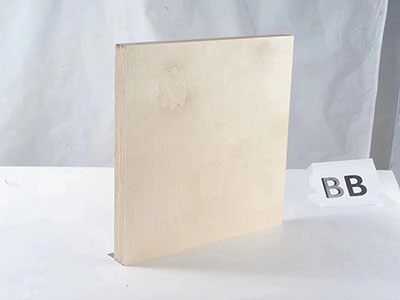

Filmless plywood is highly favored in the production of truck floors, sidewalls, and vehicle bodies due to its practical advantages:

This type of plywood provides an effective solution for industrial and transportation applications, ensuring long-lasting performance with minimal maintenance.

A plywood packing case is designed to meet the specific standards required for industrial transportation and storage. Unlike standard wooden crates, plywood packing cases are produced in custom sizes to suit various cargo needs, providing an additional layer of protection.

These cases are ideal for transporting delicate or sensitive goods, ensuring that they remain secure and undamaged during shipment. With their durability and strength, plywood packing cases offer a reliable solution for export packaging, industrial transport, and fragile equipment handling.

Marine plywood is a high-quality wood panel specially engineered to withstand moisture and harsh environments. It is made from premium wood veneers bonded with waterproof adhesives, typically using WBP (Weather and Boil Proof) phenolic resin. This adhesive ensures that the plywood remains resistant to water exposure and will not degrade or react with moisture.

To meet marine-grade standards, marine plywood undergoes rigorous testing, including a 72-hour boiling water test, to verify its strength, waterproof capabilities, and long-term durability. These properties make it an excellent choice for:

Its superior moisture resistance and structural stability ensure reliable performance in environments where ordinary plywood would fail.

Marine plywood is typically made using birch, pine, and beech veneers, each offering specific properties:

For high-performance marine environments, birch plywood is the most reliable option, ensuring long-term durability and resistance to the challenges of marine and coastal settings.

Shanghai Sindo Panel Company Ltd., located in the biggest city of China, Shanghai, is a manufacturer and exporter of various kind of wood products from China. Founded in 2002, we offer a wide variety of wood products including plywood, film faced plywood, Plain MDF, Hardboard, and different kinds of fancy items, like Melamine / paper / veneer / polyster faced items. With over twenty years of experience in the manufacturing and exporting of wood products, we have created our own trademark and brand, "Sindoply", "Sindoplex",” Falconply", Swan", and "Spark". Which are famous and well accepted by the clients all over the world. We also can offer OEM service. Our major market include Mid east area ( Dubai, Saudi, Qatar, Kuwait, Oman, Bahrain), African countries ( Algeria, Nigeria, Egypt, Kenya, Sudan), Europe ( Germany, France, Romania, Georgia), North America ( USA, Canada, Mexico), South America ( Chile, Peru), Australia, New Zealand and some Asian countries.